Car manufacturer Henry Ford s 1908 Model T automobile was his twentieth design over a five-year period that began with the production of the original Model A in 1903. With his Model T, Ford finally achieved two objectives. He had a car that was designed for manufacture, and one that was easily operated and maintained by the owner. These two achievements laid the groundwork for the revolutionary change in direction for the entire motor vehicle industry.

The key to mass production wasn’t the moving, or continuous, assembly line. Rather, it was the complete and consistent interchangeability of parts and the simplicity of attaching them to each other. These were the manufacturing innovations that made the assembly line possible. To achieve interchangeability, Ford insisted that the same gauging system be used for every part all the way through the entire manufacturing process. Previously, each part had been made to a slightly different gauge, so skilled fitters had to file each part individually to fit onto the other parts of the car. Ford’s insistence on working to gauge throughout was driven by his realisation of the payoff he would get in the form of savings on assembly costs. Ford also benefited from recent advances in machine tools able to work on pre-hardened metals. The warping or distortion that occurred as machined parts were being hardened had been the bane of previous attempts to standardise parts. Once the warping problem was solved, Ford was able to develop innovative designs that reduced the number of parts needed and made these parts easy to attach. For example, Ford’s four-cylinder engine block consisted of a single, complex casting. Competitors cast each cylinder separately and bolted the four together. Taken together, interchangeability, simplicity, and ease of attachment gave Ford tremendous advantages over his competition.

Ford’s first efforts to assemble his cars, beginning in 1903, involved setting up assembly stands on which a whole car was built, often by one fitter. In 1908, on the eve of the introduction of the Model T, a Ford assembler’s average task cycle, that is the amount of time he worked before repeating the same operations, totalled 514 minutes, or 8.56 hours. Each worker would assemble a large part of a car before moving on to the next. For example, a worker might put all the mechanical parts, such as wheels, springs, motor, transmission and generator, on the chassis (body), a set of activities that took a whole day to complete. The assembler/fitters performed the same set of activities over and over at their stationary assembly stands. They had to get the necessary parts, file them down so they would fit (Ford hadn’t yet achieved perfect interchangeability of parts), then bolt them in place.

The first step Ford took to make this process more efficient was to deliver the parts to each workstation. Now the assemblers could

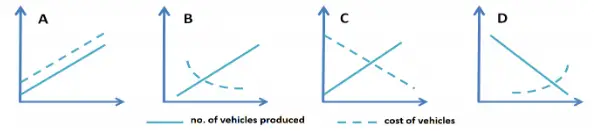

remain at the same spot all day. Later in 1908, when Ford finally achieved perfect part interchangeability, he decided that the assembler would perform only a single task and move from vehicle to vehicle around the assembly hall. By August of 1913, just before the moving assembly line was introduced, the task cycle for the average Ford assembler had been reduced from 514 to 2.3 minutes. Naturally, this reduction spurred a remarkable increase in productivity, partly because complete familiarity with a single task meant the worker could perform it faster, but also because all filing and adjusting of parts had by now been eliminated. Workers simply popped on parts that fitted every time.

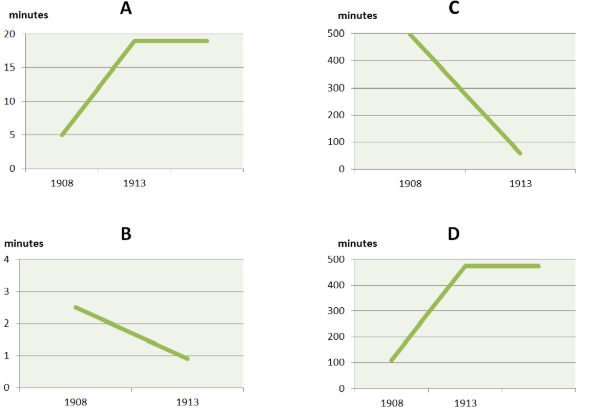

Ford soon recognised the problem with moving the worker from assembly stand to assembly stand: walking, even if only for a yard or two, took time, and jam-ups frequently resulted as faster workers overtook the slower workers in front of them. Ford’s stroke of genius in the spring of 1913, at his new Highland Park plant in Detroit, was the introduction of the moving assembly line, which brought the car past the stationary worker. This innovation cut cycle time from 2.3 minutes to 1.19 minutes; the difference lay in the time saved in the worker’s standing still rather than walking and in the faster work pace which the moving line could enforce. The moving assembly sped up production so dramatically that the savings Ford could realise from reducing the inventory of parts waiting to be assembled far exceeded this trivial outlay.

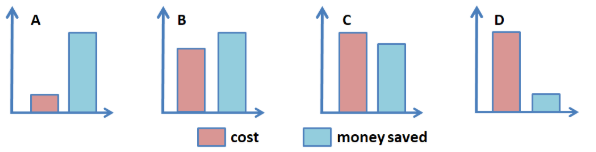

Even more striking, Ford’s discovery simultaneously reduced the amount of human effort needed to assemble an automobile. What’s more, the more vehicles Ford produced, the more the cost per vehicle fell. Even when it was introduced in 1908, Ford’s Model T, with its fully interchangeable parts, cost less than its rivals. By the time Ford reached peak production volume of 2 million identical vehicles a year in the early 1920s, he had cut the real cost to the consumer by an additional two-thirds.

To appeal to his target market of average consumers, Ford had also designed unprecedented ease of operation and maintainability into his car. He assumed that his buyer would be a farmer with a modest tool kit and the kinds of mechanical skills needed for fixing farm machinery. So the Model T’s owner’s manual explained in 64 pages how the owner could use simple tools to solve any of the 140 problems likely to occur with the car.

Ford’s competitors were as amazed by this designed-in repairability as by the moving assembly line. This combination of competitive advantages catapulted Ford to the head of the world’s motor industry and virtually eliminated craft-production companies unable to match its manufacturing economies.

Questions 27-32

Complete the flow chart below. Choose NO MORE THAN THREE WORDS from the passage for each answer. Write your answers in boxes 27-32 on your answer sheet.

IMPROVING PRODUCTIVITY

• Manufacturing innovations gave Ford a huge advantage over the (27)…………………

ASSEMBLING THE CAR

• Assembly stands set up

• (28)………………………..performed repeatedly.

MAKING THE PROCESS MORE EFFICIENT

• Parts delivered to (29)…………………….

• Fitter remained stationary all day.

ACHIEVING PERFECT (30)………………

• Fitter carried out a single task only.

• Assembler moved around the hall from car to car.

• Reduction in the (31)…………………….increased productivity.

INTRODUCING THE MOVING ASSEMBLY LINE

• Vehicle moved from one workstation to the next

• Increase in (32)……………………….implemented because of the stationary assembler.

Questions 33-37

According to the passage, classify the following characteristics of mass production as relating to

A an advantage

B a disadvantage

C neither an advantage nor a disadvantage

33. shaping each part to fit individually with all other parts

34. having a single, complex casting for the four-cylinder engine block

35. designing 20 Ford automobiles within a five-year period

36. hardening of machined parts for standardisation

37. using identical gauges for each part throughout the production

Questions 38-40

Choose the appropriate letter, A, B, C or D.

38. Which graph best describes the change in task time resulting from workers performing a single task only?

39. Which graph best describes the cost of building a moving assembly line in comparison to the money saved?

40. Which graph best describes the relationship between the number of vehicles produced and the cost of the vehicles?